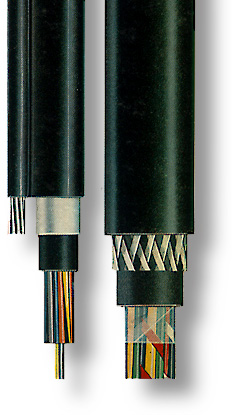

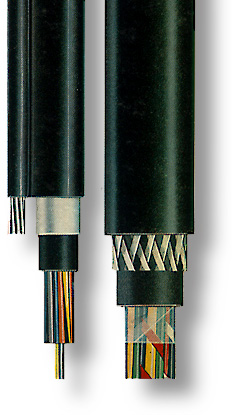

Low frequency self-supporting junction cable

TD 39-UP, TD 59-UP, TD 39-CP, TD 53-CPAPLICATION

Low frequency self-supporting cables of these

types are applied for creating a quality network line connections. They are distinguished

with reduced oprating capacity ,better mechanical protection and a better moisture

protection .They are installed on poles as a rule , as well as underground at shorter

distance.

Permissible temperature ranges :

at laying from -5 up to + 50 ° C before and after laying from - 30° C up to + 50° C

The use of these cables in power purposes is not permitted.

The maximum oprating voltage value is 150 V a.c. and 210 V d.c.

Make-up

| Construction elements |

Cables |

| |

TD 39-UP |

TD 59-UP |

TD 39-CP |

TD 53-CP |

| Conductor diameter |

0,8 ili 0,9 mm |

| Conductor insulation. |

Compact

PE |

Foamed

PE |

Compact

PE |

Foamed |

| Twisting element . |

Star quad |

Cable core with conductor.

0,8 mm

0,9 mm |

3, 5, 7, 10 i 15quads

5, 7 i 10quads |

| Belt insulation |

Several thermoplastic tapes |

| Unutrašnji PE omot. debljine |

0,8 mm |

1,0 mm |

| Screen |

ALUMONIUM TAPE

LONGITUDINALY, COVERED WITH EITHER SIDES BY ETHYLEN COPOLYMER WITH OVERLAP |

| sUPPORING ELEMENT |

STEEL WIRE STRANDED

WIRES

1,0 OR 1,2 mm |

Flat steel wire

braid |

| Outer PE sheath |

In shape of

"8" 1.8 to 2.0 mm thickness in thight connection with Al tape. |

Closed in a braid

min. 2.4 mm thickness |

Colour coding

Core colours within a quad are different .Distinction of individual parts is carried

out trough a-wire . Colour of a- wire , as well as other wires is specified in Table : |

|

|

I pair |

|

II pair |

| Quad in cable |

|

a-wire |

|

b-wire |

|

c-wire |

|

d-wire |

| First - Marker |

|

|

|

|

|

|

|

|

| Direction |

|

|

|

|

|

|

|

|

| Odd |

|

|

|

|

|

|

|

|

| Even |

|

|

|

|

|

|

|

|

|

PackingCables are supplied

at stupilated factory lengths with sealed ends. |

|

|

|

|

Make-up |

|

|

|

Aprox.

Inner

Sheat

Dia. |

|

|

|

Approx.

Cable

Height

|

|

|

|

Supporting

Strand |

|

|

|

Aprox.

Cable

Weight |

|

|

|

Factory

Lenght |

|

|

|

|

|

|

|

|

mm |

|

|

|

mm |

|

|

|

mm |

|

|

|

kg/km |

|

|

|

m |

|

|

|

----------------------- |

|

----------------- |

|

----------------- |

|

----------------- |

|

----------------- |

|

------------------- |

|

|

|

TD 39-UP |

|

|

|

|

3 X 4 X 0,8 |

|

|

|

15,5 |

|

|

|

24,0 |

|

|

|

7 X 1,2 |

|

|

|

326 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,8 |

|

|

|

18,0 |

|

|

|

27,0 |

|

|

|

12 X 1,0 |

|

|

|

431 |

|

|

|

500 |

|

|

|

|

7 X 4 X 0,8 |

|

|

|

20,0 |

|

|

|

30,0 |

|

|

|

12 X 1,2 |

|

|

|

547 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,8 |

|

|

|

24,0 |

|

|

|

34,0 |

|

|

|

19 X 1,0 |

|

|

|

722 |

|

|

|

500 |

|

|

|

|

15 X 4 k 0,8 |

|

|

|

27,0 |

|

|

|

38,0 |

|

|

|

19 X 1,2 |

|

|

|

954 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,9 |

|

|

|

19,0 |

|

|

|

28,0 |

|

|

|

12 X 1,2 |

|

|

|

532 |

|

|

|

500 |

|

|

|

|

7 X 4 X 0,9 |

|

|

|

21,0 |

|

|

|

31,0 |

|

|

|

19 X 1,0 |

|

|

|

614 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,9 |

|

|

|

27,0 |

|

|

|

38,0 |

|

|

|

19 X 1,2 |

|

|

|

796 |

|

|

|

500 |

|

|

|

|

TD 59-UP |

|

|

|

|

3 X 4 X 0,8 |

|

|

|

13,5 |

|

|

|

21,5 |

|

|

|

7 X 1,2 |

|

|

|

278 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,8 |

|

|

|

15,2 |

|

|

|

25,0 |

|

|

|

12 X 1,0 |

|

|

|

378 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,8 |

|

|

|

15,2 |

|

|

|

25,0 |

|

|

|

12 X 1,0 |

|

|

|

378 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,8 |

|

|

|

20,0 |

|

|

|

29,5 |

|

|

|

19 X 1,0 |

|

|

|

594 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,8 |

|

|

|

20,0 |

|

|

|

29,5 |

|

|

|

19 X 1,0 |

|

|

|

594 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,8 |

|

|

|

17,0 |

|

|

|

27,0 |

|

|

|

12 X 1,2 |

|

|

|

461 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,8 |

|

|

|

17,0 |

|

|

|

27,0 |

|

|

|

12 X 1,2 |

|

|

|

461 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,9 |

|

|

|

21,0 |

|

|

|

31,5 |

|

|

|

19 X 1,2 |

|

|

|

727 |

|

|

|

500 |

|

|

|

|

|

Make-up |

|

|

|

Aprox. |

|

|

|

Noseći oplet |

|

|

|

Aprox. |

|

|

|

Factory |

|

|

|

|

|

|

|

|

Cable

Dia. |

|

|

|

No.

Wire |

|

|

|

Tensile

Strenght |

|

|

|

Load |

|

|

|

Cable

Weight |

|

|

|

Lenght |

|

|

|

|

|

|

|

|

mm |

|

|

|

mm |

|

|

|

mm |

|

|

|

mm |

|

|

|

kg/km |

|

|

|

m |

|

|

|

----------------------- |

|

----------------- |

|

----------------- |

|

----------------- |

|

------------------- |

|

----------------- |

|

------------------- |

|

|

|

TD 33-CP |

|

|

|

|

3 X 4 X 0,8 |

|

|

|

17,0 |

|

|

|

24 |

|

|

|

1600 |

|

|

|

800 |

|

|

|

376 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,8 |

|

|

|

19,5 |

|

|

|

36 |

|

|

|

2400 |

|

|

|

1200 |

|

|

|

564 |

|

|

|

500 |

|

|

|

|

7 X 4 X 0,8 |

|

|

|

21,0 |

|

|

|

36 |

|

|

|

2400 |

|

|

|

1200 |

|

|

|

652 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,8 |

|

|

|

25,5 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

16D0 |

|

|

|

969 |

|

|

|

500 |

|

|

|

|

15 X 4 X 0,8 |

|

|

|

28,0 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

1600 |

|

|

|

1164 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,9 |

|

|

|

21,5 |

|

|

|

36 |

|

|

|

2400 |

|

|

|

1200 |

|

|

|

647 |

|

|

|

500 |

|

|

|

|

7 X 4 X 0,9 |

|

|

|

23,5 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

1600 |

|

|

|

766 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,9 |

|

|

|

28,5 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

1600 |

|

|

|

1135 |

|

|

|

500 |

|

|

|

|

TD 53-CP |

|

|

|

|

3 X 4 X 0,8 |

|

|

|

15,0 |

|

|

|

24 |

|

|

|

1600 |

|

|

|

800 |

|

|

|

332 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,8 |

|

|

|

17,0 |

|

|

|

36 |

|

|

|

2400 |

|

|

|

1200 |

|

|

|

487 |

|

|

|

500 |

|

|

|

|

7 X 4 X 0,8 |

|

|

|

18,0 |

|

|

|

36 |

|

|

|

2400 |

|

|

|

1200 |

|

|

|

551 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,8 |

|

|

|

21,0 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

1600 |

|

|

|

777 |

|

|

|

500 |

|

|

|

|

15 X 4 X 0,8 |

|

|

|

24,0 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

1000 |

|

|

|

963 |

|

|

|

500 |

|

|

|

|

5 X 4 X 0,9 |

|

|

|

18,0 |

|

|

|

36 |

|

|

|

2400 |

|

|

|

1200 |

|

|

|

547 |

|

|

|

500 |

|

|

|

|

7 X 4 X 0,9 |

|

|

|

19,0 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

1600 |

|

|

|

624 |

|

|

|

500 |

|

|

|

|

10 X 4 X 0,9 |

|

|

|

22,5 |

|

|

|

48 |

|

|

|

3100 |

|

|

|

1600 |

|

|

|

866 |

|

|

|

500 |

|

|

|