Cable

accessories

HEAT-SHRINKABLE CAPS TSK, TSKL and

TSKLv

surface, so the complete sealing at pressure and humidity

is achieved. The advantageous chracteristics of the heat-shrinkable caps are:

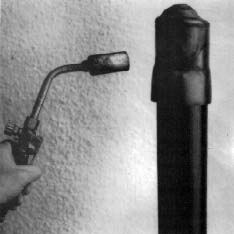

CONSTRUCTION

Heat-shrinkable caps are made of cross-linked polyethylene. They are coated internally

with thermoplastic glue by special proceedings. If required, a valve may be assembled on

the top of the caps.

APPLICATION

They are used for hermetic closing of all power and telecommunication cable ends. The caps

with assembled valve are used for closing ends of telecommunication cables with gas

control.

TECHNICAL CHARACTERISTICS

The size of heat-shrinkable cap is choosen, so the cap can be pushed on the cable end

easily. The cap is shrinked by heating at temperature around 125 0C and the

glue is melted, filling all roughness on the cable sheath

- simple and fast mounting

- high mechanical hardness

- resistance on alifatic and water aromatic carbon hydrogen,

soil salt and alkali

- very good resistance on aging and atmospheric influence

- unlimmited shelf life

The heat-shrinkable caps are choosen according to cable

outer diameter. Technical data of the caps are shown in the following table.

| Range of

application |

|

Dimension (mm) |

| Outer diameter |

MARK |

Before shrinking |

After

shrinking |

| from - to |

|

D |

D1 |

b |

L |

L1 |

| 5 - 9 |

TSK 10/4 |

10 |

4 |

2,0 |

33 |

30 |

| 9 - 14 |

TSK 17/7 |

17 |

7 |

2,5 |

60 |

55 |

| 14 - 24 |

TSK 28/12 TSKL 28/12 |

28 |

12 |

3,5 |

90 |

80 |

| 24 - 43 |

TSK 48/22 TSKL48/22 |

48 |

22 |

4,0 |

140 |

130 |

| 43 - 75 |

TSK80/40 TSKL 80/40 |

80 |

40 |

4,0 |

160 |

140 |

| 75 - 110 |

TSK115/65 TSKL 115/65 |

115 |

65 |

4,0 |

160 |

140 |

Legend

TSK ? heat-shrinkable caps without glue

TSKL ? heat-shrinkable caps with thermoplastic glue

TSKLv ? heat-shrinkable caps with thermoplastic glue and assembled valvem

HEAT-SHRINKABLE TUBES TSC

and TSCO

APPLICATION

Heat-shrinkable tubes are used in wide range of application:

- in electrical instalation

- as protection of metal parts against erosion

- for sealing of cable glands in buildings against penetration of water and harmful

gas

- for sealing of cable termination

- for insulating of cable terminal lugs

- as outer protection of the joint and for reparation of damaged cable sheath near

the joint

- as primary insulation of the joint for low voltage

- for insulating of the buses in power plant

CONSTRUCTION

Heat-shrinkable tubes are made of cross-linked polyethylene.

During the heating at temperature around 125 0C, the tubes are shrinked,

accomodating the form of comprised object and achieving complete sealing. The heating is

carried out with wide yellow flame from the middle towards the ends of the tube. The

tubes, marked with TSCL and TSCOL are coated internally with thermoplastic glue by special

proceedings.

PROPERTIES

- simple and fast mounting

- high mechanical hardness

- resistance on alifatic and water aromatic carbon hydrogen, soil salt and alkali

- very good resistance on aging and atmospheric influence

- unlimmited shelf life

- good electrical properties

TECHNICAL DATA

Volume mass (kg/m3) 30 ? 1050

Tensile strength (MPa) > 12,5

Expansion (%) > 250

Hardness ( 0shD) 40 ? 50

Dielectric strength (kV/mm) > 15

Relative permittivity < 3,5

Specific electrical resistance (-cm) > 10 12

Condition at high temperature 7 days at 135 0C

Longitudinal shrinking during the heating for tubes on the reel (%) 15 ?

5

Longitudinal shrinking during the heating for 1 m tubes (%) < 10

Loss factor tg- < 0,004

The heat-shrinkable tubes are choosen according to cable

outer diameter. Technical data of the tubes are shown in the following table.

Optimal

range of application |

|

Dimension

mm |

Optimal

range of application |

|

Dimension

mm |

Outer

diameter

mm |

mark |

Before shrinking |

After

shrinking |

Lenght |

Outer

diameter

mm |

mark |

Before shrinking |

After

shrinking |

Lenght |

| from - to |

|

D1 |

D |

- |

mm |

Od Do |

|

D1 |

D |

- |

mm |

| 2,5 - 6,5 |

TSC 6/2 |

6 |

2 |

1,5 |

|

1 - 2,5 |

TSCO 3/1 |

3,4 |

1 |

0,5 |

|

| 5 - 11 |

TSC 12/4 |

12 |

4 |

1,5 |

|

2 - 5 |

TSCO 6/2 |

6,4 |

2 |

1 |

On the |

| 11 - 24 |

TSC 25/10 |

25 |

10 |

3 |

|

8 - 18 |

TSCO 20/7 |

20 |

7 |

1,5 |

reel |

| 14 - 33 |

TSC 35/13 |

35 |

13 |

3,5 |

|

15 - 30 |

TSCO 35/13 |

35 |

13 |

1,8 |

od 25 |

| 18 - 40 |

TSC 42/16 |

42 |

16 |

3,5 |

|

18 - 36 |

TSCO 42/16 |

42,4 |

16 |

2 |

do 100 m |

| 22 - 51 |

TSC 53/21 |

53 |

21 |

4 |

1000 |

25 - 52 |

TSCO 53/21 |

53 |

21 |

2 |

|

| 28 - 60 |

TSC 63/27 |

63 |

27 |

4 |

|

35 - 75 |

TSCO 80/32 |

80 |

32 |

2,1 |

|

| 35 - 78 |

TSC 80/32 |

80 |

32 |

4 |

|

45 - 98 |

TSCO 105/42 |

105 |

42 |

2,6 |

1000 |

| 45 - 95 |

TSC 100/42 |

100 |

42 |

4 |

|

58 - 125 |

TSCO 135/54 |

135 |

54 |

2,7 |

|

| 60 -125 |

TSC 132/56 |

132 |

56 |

4 |

|

90 - 180 |

TSCO 200.80 |

200 |

80 |

3,2 |

|

| 90 - 200 |

TSC 205/85 |

205 |

85 |

4 |

|

|

|