Cable

accessories

INDOOR CABLE TERMINAL BOX

KGTu 10

APPLICATION

Indoor cable terminal boxes are used for terminating three

core paper insulated cables, 10 kV (classical or "NON-DRAINING"). They are

produced in two variants: protection of cable cores with oil resistance heat-shrinkable

tubes or with heat-shrinkable tubes with inner adhesive layer.

CONSTRUCTION

Terminal box is made of glass, which has excellent

mechanical and electrical properties and enables control oil level. If required, oil can

be poured. Both the caps on the top and metal cone are made of tinned brass.

Heat-shrinkable tubes enable good sealing of cable terminal box. Conductor is connected

with cable lugs (copper or bimetal). Data for choice of indoor cable terminal box KGTu are

shown in the following table.

.

| Type |

Cross-section (mm2) |

Dimensions

of sector sections

h × b (mm) |

Diameter of opening in box (mm) |

| KGTu - 1 |

50 70 95 |

13,38 × 19,47

14,71 × 21,70

16,43 × 24,0 |

32 |

| KGTu - 2 |

120 150 185 |

17,39 × 26,35

18,69 × 29,04

20,03 × 31,13 |

45 |

| KGTu - 3 |

240 300 |

22,38 × 34,68

23,94 × 37,81 |

55 |

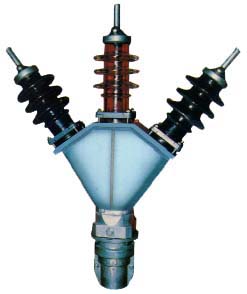

OUTDOOR CABLE TERMINAL BOX

KGTs 10

APPLICATION

Outdoor cable terminal boxes are used for terminating three core

paper insulated cables with copper or aluminium conductor cross-sections up to 240 mm2

and voltage up to 12 kV.

CONSTRUCTION

Terminal box KGTs 10 consists of:

- Box of aluminium alloy

- Three glass or porcelain isolators

- Tined copper or brass cone for sealing cable and terminal box.

Connection conductors and cable connectors can be carried out by soldering or

crimping. Terminal box is connected to overhead line conductors or other elements of power

construction with special connection clamps. After mounting, terminal box is filled with

oil compound. Total mass of terminal box without oil compound and connections elements is

approx.13kg..

TERMINAL

BOX KGTsz 35 and KGJs 35

APPLICATION

Cable terminal box KGTsz 35 is used for terminating three core

power cables with paper insulation and lead sheath over each core cables, with copper or

aluminium conductors, 20-35 kV. Cable terminal box KGJsz is used for terminating single

core cables with paper insulation, with copper or aluminium conductors for voltages 20-35

kV.

CONSTRUCTION

Terminal Box consist of:

- Three glass or porcelain insulators

- Supporter for insulators

- Cable gland

- Dividing box

These terminal boxes are filled up with high voltage

"NON-DRAINING" oil compound. Both the caps on the top and metal cone are made of

tined brass. Connection of the cap to overhead line conductors or other elements of power

construction are made with screw clamps, insulated conductors or compression type terminal

lugs. The cable cores terminating is carried out by copper or aluminium- copper

connectors. These terminal box is proved according to VDE 0278 standard.

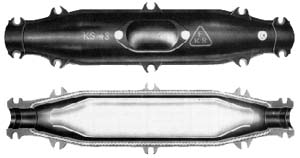

STRAIGHT THROUGH JOINTS BOXES

KS FOR POWER CABLES

APPLICATION

Straight through joint boxes type KS, according to JUS N.F4.031

standard, are applied for jointing the power cables with impregnated paper insulation:

- Straight through joint boxes type KS with lead sleeve for cables with common

metal coating, nominal voltage 1-10 kV(choice according to table 1);

- Straight through joint boxes type KS/H with lead sleeve for cables with common

metal coating, nominal voltage 15-35 kV (choice according to table 2);

- Straight through joint boxes type KS/HE with lead sleeves for cables with metal

coating over each core, nominal voltage 15-35 kV (choice according to table 3);

- Straight trough joints boxes type KS/P with lead sleeve for cables in various

constructions, one with common and other with separate metal coating over each core,

nominal voltage 20-35 kV (choice according to table 4);

- Branch joints boxes type KSR with or without lead sleeve for in cases of

branching uncut and cut cables, nominal voltage 1-10 kV (choice according to table 5).

All protective boxes (outdoor protection) are made of cast iron

with cover, except special boxes KS up to 10 kV, which have protection of heat-shrinkable

tube. Protective boxes are filled up with bitumen compound and lead sleeves are filled up

with high voltage oil compound.

Table 1.

| Type of |

Lead |

Cross-section (mm2) |

Dimensions

ca. mm |

Weight

ca. kg |

| joint box |

sleeve |

single

core

1 kV |

two

cores

1 kV |

three

cores

1, 6 and

10 kV |

four cores

1-10 kV |

l1 (L) |

l2 |

l3 |

d1 |

d2 |

h |

b (D) |

Sleeve |

Filling

compo-und |

| KS 19 |

KSU 19 |

6-95 |

2,5-35 |

2,5-25 (1) |

25-16 |

450 |

354 |

264 |

30 |

61 |

115 |

122 |

5,6 |

2,0 |

| |

|

|

|

35-50 (1) |

|

|

|

|

|

|

|

|

|

|

| KS 26 |

KSU 26 |

120-185 |

50-95 |

6-25 (6) |

25-35 |

550 |

442 |

352 |

37 |

74 |

129 |

135 |

8,5 |

3,5 |

| |

|

|

|

10 (10) |

|

|

|

|

|

|

|

|

|

|

| KS 26-S |

|

|

|

do 25 (10) |

|

800 |

|

|

|

|

|

100 |

- |

- |

| |

|

|

|

70-120 (1) |

|

|

|

|

|

|

|

|

|

|

| KS 34 |

KSU 34 |

240-400 |

120-150 |

35-70 (6) |

50-95 |

655 |

532 |

442 |

45 |

88 |

154 |

178 |

15 |

5,5 |

| |

|

|

|

25-50 (10) |

|

|

|

|

|

|

|

|

|

|

| KS 34-S |

|

|

|

|

|

900 |

|

|

|

|

|

115 |

- |

- |

| |

|

|

|

150-185 (1) |

|

|

|

|

|

|

|

|

|

|

| KS 43 |

KSU 43 |

500-630 |

185-240 |

95-120 (6) |

120-150 |

765 |

624 |

532 |

54 |

101 |

166 |

193 |

20,6 |

8 |

| |

|

|

|

70-120 (10) |

|

|

|

|

|

|

|

|

|

|

| KS 43-S |

|

|

|

|

|

1000 |

|

|

|

|

|

125 |

- |

- |

| |

|

|

|

240-300 (1) |

|

|

|

|

|

|

|

|

|

|

| KS 53 |

KSU 53 |

800-1000 |

300-400 |

150-240 (6) |

185-240 |

800 |

718 |

614 |

64 |

114 |

180 |

210 |

28,8 |

11,5 |

| |

|

|

|

150-185 (10) |

|

|

|

|

|

|

|

|

|

|

| KS 53-S |

|

|

|

|

|

1100 |

|

|

|

|

|

135 |

- |

- |

| |

|

|

|

400 (1) |

|

|

|

|

|

|

|

|

|

|

| KS 64 |

KSU 64 |

- |

- |

300-400 (6) |

300 |

1000 |

814 |

696 |

75 |

128 |

195 |

220 |

35,6 |

16 |

| |

|

|

|

240-300 (10) |

|

|

|

|

|

|

|

|

|

|

| KS 64-S |

|

|

|

|

|

1150 |

|

|

|

|

|

150 |

- |

- |

Table 2.

| Type of |

Lead |

Cross-section |

Dimensions

ca. mm |

Weight

ca. kg |

| joint box |

sleeve |

(mm2) |

l1 |

l2 |

l3 |

d1 |

d2 |

h |

b |

Cast

iron box |

Lead

sleeve |

Compound

VUM |

Compound

SP |

| KS 1150/H |

KSU 820 |

16-150 (15kV) |

1150 |

960 |

820 |

90 |

144 |

220 |

248 |

39 |

16,5 |

10 |

10 |

| KS 1350/H |

KSU 950 |

185-240 (15 kV) 16-150 (20 kV) |

1350 |

1100 |

950 |

105 |

158 |

250 |

280 |

68 |

20 |

13,5 |

14 |

| KS 1640/H |

KSU 1170 |

185-240 (20 kV) 35-240 (35 kV) |

1640 |

1320 |

1170 |

120 |

178 |

300 |

326 |

94 |

28,5 |

20 |

31 |

Table 3.

| Type of |

Lead |

Cross-section |

Dimensions

ca. mm |

Weight

ca. kg |

| joint box |

sleeve |

(mm2) |

l1 |

l2 |

l3 |

d1 |

d2 |

h |

b |

Cast

iron box |

Lead

sleeve |

Compound

VUM |

Compound

SP |

| KS 1150/HE |

KSU 470 |

16-150 (15kV) |

1150 |

960 |

470 |

90 |

68 |

220 |

248 |

39 |

11 |

3 |

17 |

| KS 1350/HE |

KSU 580 |

185-240 (15 kV) 16-150 (20 kV) |

1350 |

1100 |

580 |

105 |

76 |

250 |

280 |

68 |

15 |

5 |

24 |

| KS 1640/HE |

KSU 750 |

185-240 (20 kV) 35-240 (35 kV) |

1640 |

1320 |

750 |

120 |

90 |

300 |

326 |

94 |

22,5 |

8 |

41 |

Table 4.

| Type of |

Lead |

Cross-section |

Dimensions

ca. mm |

Weight

ca. kg |

| joint box |

sleeve |

(mm2) |

l1 |

l2 |

l3 |

d1 |

d2 |

h |

b |

Cast

iron box |

Lead

sleeve |

Compound

VUM |

Compound

SP |

| KS 1640/P |

KSU 1070 |

25-240 (20 kV) 35-240 (35 kV) |

1640 |

1320 |

1070 |

120 |

178 |

300 |

326 |

94 |

27 |

19 |

30 |

Table 5.

| Type of |

Lead |

Cross-section (mm2) |

Dimensions

ca. mm |

Weight ca.

kg |

| joint box |

sleeve |

single

core

1 kV |

two

cores

1 kV |

three

cores

1, 6 and

10 kV |

four cores

1-10 kV |

l1 (L) |

l2 |

l3 |

d1 |

d2 |

h |

Sleeve |

Filling

compo-und |

| |

|

|

|

35-50 (1) |

|

|

|

|

|

|

|

|

|

| KSR 26 |

KSRU 26 |

do 185 |

do 50 |

6-25 (6) |

do 25 |

570 |

462 |

362 |

231 |

37 |

126 |

11 |

5 |

| |

|

|

|

10 (10) |

|

|

|

|

|

|

|

|

|

| |

|

|

|

70-120 (1) |

|

|

|

|

|

|

|

|

|

| KSR 34 |

KSRU 34 |

240-400 |

70-95 |

35-70 (6) |

35-50 |

680 |

558 |

434 |

280 |

45 |

160 |

18 |

7 |

| |

|

|

|

25-50 (10) |

|

|

|

|

|

|

|

|

|

| |

|

|

|

150-185 (1) |

|

|

|

|

|

|

|

|

|

| KSR 43 |

KSRU 43 |

500-630 |

120-150 |

95-120 (6) |

70-95 |

780 |

640 |

492 |

320 |

54 |

177 |

24,5 |

10 |

| |

|

|

|

70-120 (10) |

|

|

|

|

|

|

|

|

|

| |

|

|

|

240-300 (1) |

|

|

|

|

|

|

|

|

|

| KSR 53 |

KSRU 53 |

800-1000 |

185-240 |

150-240 (6) |

120-150 |

880 |

720 |

557 |

360 |

64 |

203 |

38 |

16 |

| |

|

|

|

150-185 (10) |

|

|

|

|

|

|

|

|

|

| |

|

|

|

400 (1) |

|

|

|

|

|

|

|

|

|

| KSR 64 |

KSRU 64 |

- |

300 |

300-400 (6) |

300 |

1100 |

824 |

692 |

462 |

75 |

254 |

44,5 |

30 |

| |

|

|

|

240-300 (10) |

|

|

|

|

|

|

|

|

|

|