|

|

| In FKS production range, all

technological processes, from treatment of raw-materials to manufacturing of final

products are interconnected in a single production whole. Constant investments in plants

expansion, reconstruction and modernization offer wide possibilities for development and

innovation of new products, what means changing or expanding of the manufacturing

programme. Many technological solutions of FKS, which are up-to-date achievements in cable

technology, for the first time are applied in our country.

|

|

|

In 1957. started manufacture of submarine cables, the electrification of the Adriatic islands. In 1963. the first domestic coaxial cable was developed, in 1971 . XLPE insulated power cables etc. Today it is VCV line for manufacture of XLPE insulated high voltage cables and heavy-duty mine power cables, then the technology of insulated conductors radiation, production of cables with non-metal conductors - optical cables, thermo-shrinkable accessories, as well as production of wide range of radiofrequency microcables, seismic cables and microcables for special purposes. In production of connectors and electromechanical products, the up-to-date technology of mechanical processing, automatic galvanisation are applied. | |

|

|

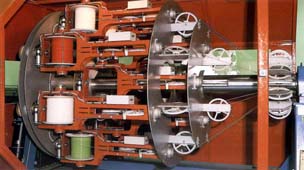

Realisation of high-quality technology is provided by application of modern equipments. All production phases in FKS are based on the up-to-date machines and units. |

| FKS has the modern electronic computer center with terminal network connecting terminal units in all FKS locations. With the permanent follow-up and data processing in a field of technical, commercial and economical business, as well as the processing of mathematical and technical information necessary for the development and other technical business, data processing is applied in all business areas. |  |

|

The quality control is integral part of manufacturing process. By the permanent control of input raw-materials and long-standing cooperation with its suppliers, FKS provides high-quality of input materials and raw-materials. | |

| Selection of those

materials results in the final products of the best quality. The optimal usage of the

available capacities is provided. The routine testing is carried out on each product

during and after its production and the type testing are carried out in the laboratories

of development and research department. New technology application and development of new products are followed with investments in the new testing installations, and today FKS has the most modern testing centers and laboratories providing the unique quality of final products. |

|

|

[ General

data ] [ Qualty system ] [ Technical

and technological potential ] [ Development and research ] [ Manufacturing programme ] :

[ Power cables ] [ Copper, aluminium and

steel products ] [ Telekommunication cables ]

[ Enameled wire ] [ Industrial

electronics ] [ Microcables and conductors ] [ Connectors and terminals ]

[ Integral parts from electroinsulated materials ] [ Heating cables and heating systems ]

[ Special programme - Medical accessories

] [ Electric cord sets and cable harnesses ]

[ Insulated power conductors ] [ Cable

accessories ] [ Engineering ] [ Equipment

]