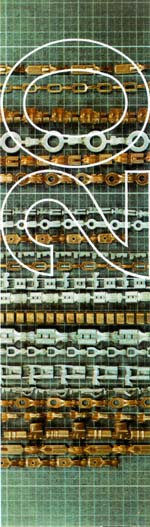

Strip Terminals

ApplicationSV serve for extension of termination of single wires being used in electrical and motor - car industry. Industrija Kablova Jagodina and depending on the application, monufacture several types of strip terminals, e.g. ring terminals, spade terminals open ring barrels, quick disconnect receptacles and tabs, ignition and snap-in contacts, etc.

Strip terminals enable a simple and quick conection of cable extension without using toois. The suitable design and quality enable lo connection and diconnection cycles without any changes of contact property.

Strip terminals B type are used individually and A type in housings providing their simultenous engagement and disengagement, thus ensuring reliable safety against contact with hardware or unit housing. Strip terminals serve for termination of one or several cables for their connectyion in the relevant damp.

Wire ignution contacts are used for jointing ignition cables in high voltage secondary circuit of vehicle ignition device with high voltage induciton cistribution system and spark plugs.

The l version is for spark plug and the ll version for distribution system.

Strip terminals enable by using serews , a firm and reliable connection of wire terminals with connection points on the unit. Type 30l is with hoale and type 303 spade version.

Printeg circuit snap-in contact is ih housing providing the direct connection of printed board lt is applied in motor -car industry.

Strip terminals fully meet DIN, FIAT AND CRVENA ZASTAVA requirements.

Terninals are supplied on plastic spools and mainly foreseen for semi-automatic and automatic installation on special equipment.

Depending on maximum operating temperature they are made of copper alloy with Zinc (tin) or steel.

| Basic material | Surface protection | Max.operating temp.0C |

| CuZn or CuSn | Unprotected | 90 |

| CuZn or CuSn | Tinned (Sn) | 110 |

| CuZn or CuSn | Silver plated (Ag) | 130 |

| Steel | Nickel plated (Ni) | 250 |

Voltage at joint drop of the connection - wire or male - female connection at current loading of 10 A is max. 7mV in copper alloy terminals and 25 mV in steel grades

Mechanical characteristics

Pulling off force depends on cable cross-section

| .Wire cross-section (mm2) |

PULLING OFF FORCE N | |

| nominal width 2,8 | nominal width 6,3, 9,5 |

|

| 0,5 | 80 | 80 |

| 0,75 | 70 | 120 |

| 1 | 80 | 160 |

| 1,5 | 200 |

|

| 2,5 | 250 |

|

| 4 | 350 |

|

| 6 | 500 |

|

| Nominal width | Pulling in force N (max.) |

PULLING OFF FORCE N | ||||

| after 1 puling in cycles max. | after 10 pulling in cycles min. | |||||

| type A | type B | type A | type B | type A | type B | |

| 2,8 | 50 | 50 | 8 | |||

| 6,3 | 12 | 80 | 12 | 80 | 6 | 20 |

| 9,5 | 100 | 100 | 40 | |||

Values are valid for galvanized terminals. Values are 20% lower for terminals without protection.